Distribution/Breakout cable sheathing line-optical cable machine

This fiber optic cable making machine sheathes indoor /outdoor disctribution multi cores optical cable, tactical fiber cable with PVC, LSZH, PE jacket, outer diameter is 11.5mm max..

Distribution/Breakout cable sheathing line-optical cable machine

Description

This fiber optic cable making machine sheathes indoor /outdoor disctribution multi cores optical cable, tactical fiber cable with PVC, LSZH, PE jacket, outer diameter is 11.5mm max..

Cable structures:

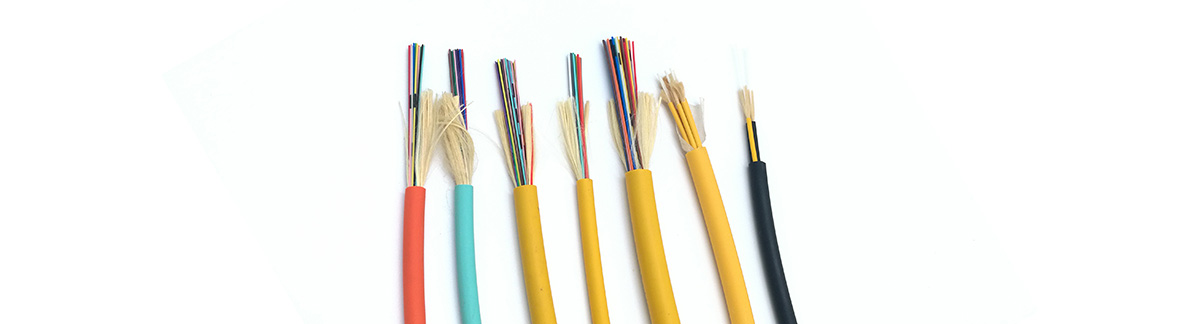

A. Indoor distribution cable with 0.6/0.9mm buffer fibers up to + Kevlar/aramid yarn strengthen members + LSZH/PVC sheath;

B. Breakout cable with 2.0mm simplex +fillers/ strengthen members + LSZH/PVC sheath;

C. Micro beakout cable with multi colored bare fiber sub-unit + fillers/ strengthen members + LSZH/PVC sheath;

D. Indoor /outdoor tactical cable, unitube PBT loose tube non-armored PE jacket cable.

And other similar optical fiber cables.

Machine component configuration is adjustable according process request (aramid yarn stranding cage is optional).

Features:

1. Precision special extruder and precision fine adjustment machine head. The applicable materials for extruder are PVC, LSZH, PE, etc.

2. The surface of the cable is smooth and smooth.

3, Cable diameter automatic feedback control, cable diameter history curve can be traced back.

4. Optical fiber is motorized releases. The tension is precisely constant and the additional loss is small.

5. The temperature control is controlled by imported OMRON temperature control meter, and the temperature control is accurate.

6. The double-reel automatic winding line is stable and reliable in operation, and the automatic winding line is formed once, without rewinding.

7. International industrial computer technology control system with high degree of automation, it can be linked with MES, ERP systems, real time tracking and managing production.

8. The main control systems and components are international famous brands, and the production line has high stability and reliability.

9. The tight-set fiber optic pay-off adopts the full-return twisted cage twisted pay-off line, the tension of the pay-off thread is stable, and it can be adjusted online.

10. The aramid pay-off line is cage twisted pay-off, passive pay-off, imported magnetic powder brake, and the tension is adjustable online.

Technical Parameters

1. Structure speed: 120m/min

2, tightly set fiber diameter; 0.6MM-0.9MM

3, tight sleeve tension: 1N-3N

4, the number of aramid line head: 24

5, aramid pay-up tension: 1N-3N

6, Fiber count: 12;

7. Length of production line: ≤55M;

8. power supply requirements: 115KVA, AC380V ±10% 50HZ three-phase five-wire;

9. Normarl machine running power consumes: ≈55KW/h.

10. Production capacity: depends on the making cable type.

Line Configuration

1250 pay-off ;

φ800 dual-wheel tension device;

Φ800mm PBT tube, FRP pay-off ;

24 heads aramid yarn pay-off (motorized aramid yarn pay-off option available);

12 heads buffer fiber twisted cage pay-off;

Mobile positioning mold platform;

φ70 Extruder;

Dryer and hopper;

Industrial PLC + IPC program control cabinet;

Mobile warm water tank + warm water tank;

4HP Chiller;

Fixed cold water sink + cold water tank;

Laser Gauge;

Inkjet bracket without printer;

Φ800 capstan;

φ800 dual-wheel tension unit;

1400 take-up machine.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Kristin shi

Phone: +8613826951514

E-mail: sales01@gfcablemachine.com

Add: Room 531, jinhui building,zhongtan Town, Dongguan, Guangdong